🎙️ | 30 | TSMC Deep Dive

With Jon from Asianometry

Buckle up! It's a TSMC deep dive. We go deep into the chip development process from start to finish, the fabs they’re constructed in, TSMC’s business model, the competitive landscape, and what the future may hold.

Talking with me about TSMC is the legend himself, Jon from Asianometry. Seriously, Jon was just next level in this one. You’d think he worked at a TSMC fab for 10 years with all the knowledge he dropped here. I mention it 8 mins in but he had my brain spinning then already.

An unreal episode, on an unreal company, with an unreal bloke explaining it. Enjoy!

Listen to this episode on Apple Podcasts, Spotify, Stitcher, Castbox, Google Podcasts, or on your favourite podcast platform.

My takeaways and lessons:

Fabs are fucking unreal!

“to give you a sense how kind of massive and undertaking this is, a fab with clean room, just 8,000 square meters needs … I looked this up … enough concrete for 25 kilometres of road, 120 kilometres of ultra-clean pipes, 250 kilometres of electric wire, 4,500 kilometres of steel bar.

It uses 24 swimming pools of ultra-pure water each hour, though that gets recycled. It uses enough compressed air to fill 3,000 balloons each minute. It runs 24/7 all the time, night and day. And guess what, a TSMC Giga fab has a clean room 13 times larger than that. Fab18 in Tainan where the N5 and N3 are being done is 20 times bigger, 160,000 square meters. And TSMC has six of those Giga fabs”The tech around TSMC is next level:

“there can be up to 600 steps for a simple 180-nanometer process chip. That’s a chip from 20 years ago that has something like 20 layers or something. Today’s chips, which are N14, N16, N10 can go up to 60, 70, 80 mask layers.”Intel has a mountain of work ahead if they want to compete

“culture-wise, TSMC is this very aggressive company. You work really long hours and you work day and night. TSMC can get away with it because they pay pretty good, labor laws are pretty weak here. But also just like people work really hard for it because it’s TSMC. It’s the Silicon sacred mountain. And I don’t think Intel has that status in the United States.”Apple 🤝 TSMC

“I think Apple anchors TSMC’s customer base. Without Apple, I don’t think TSMC gets to be the giant that it is today. So, yes, there is a failure mode where Apple one day announced they will second source M1 chips from Samsung or Intel, then TSMC stock is going to take a massive hit. […]

That being said, I think Apple and TSMC work really closely together, and it’s really hard to step off that treadmill when you’re on it. Apple and TSMC get to work together and define their process development kit, the PDK. It’s called Design Technology Co-Optimization. It’s really, really tight. Literally, the TSMC engineers will tell Apple engineers, you can’t arrange these logic gates this way because it’s not going to project, it’s not going to yield. The Apple engineers will say we will redraw the gates elsewhere. […]

I don’t think Apple can build their own semiconductor fabs. They’re kind of already moving beyond that. They’re kind of moving towards the system integrator of Boeing model where they’re accurately picking and choosing suppliers and interesting technologies to integrate into their systems.”

Mentioned/Recommended Content:

Show Notes:

[00:00:31] – [First question] – Some background on TSMC

[00:03:44] – The chip development process

[00:05:36] – The science behind it

[00:08:52] – What do the fabs look like?

[00:11:19] – Why do fabs need so much water?

[00:13:26] – Why are fabs getting bigger?

[00:14:46] – Apple and TSMC’s relationship

[00:16:24] – ASML and TSMC’s relationship

[00:20:41] – CAPEX, Competition and a potential glut?

[00:24:47] – Taiwan and TSMC’s relationship

[00:27:05] – Would Apple ever compete with TSMC?

[00:30:43] – TSMC Q4 Results and future plans

[00:35:48] – Why is TSMC so secretive around their fabs

[00:37:37] – Can the US feasibly compete in the semiconductor space?

[00:40:15] – Is Moore’s law really dead?

[00:42:33] – Anything else that’s consequential about TSMC’s future?

Connect with Jon:

Sometimes your email provider will cut off the latter part of this email, so to read the full transcript, click the button below ↓

Transcript

Kalani Scarrott (00:31): All right, how are we doing? So my guest today is Jon from Asianometry. Jon is the creator of the hugely popular Asianometry YouTube channel, where he posts video essays on business, technology and history within Asia. Today’s conversation is all about TSMC. We go deep on the chip development process from start to finish, the fabs they’re constructed in, TSMC’s business model, the competitive landscape and what the future may hold.

So just for reference, this episode was recorded on January 25th, 2021. So I hope you enjoy this deep dive on TSMC with Jon from Asianometry. Cool. Jon, cheers so much for being on today again. A fun way for me to start is maybe your history and background with the topic we’re about to dive deep into. So, what’s your history with TSMC? What’s got you interested, and yeah, take it however you want.

Jon (Asianometry) (01:20): So for me, like myself and TSMC, it’s interesting though, I don’t speak to TSMC people. I almost never hear from them. I got a lot of emails from ASML people, employees, but I’ve never really heard anything from TSMC. I feel like they don’t know I exist. They probably couldn’t care less. They’re too busy running their fabs. I can’t really say I’m passionate about TSMC. I don’t really talk to people about it, but it gets the people going as the Jay-Z song goes.

Taiwan is obsessed with TSMC. It’s been the case for a very long time. It’s really hard to put it in perspective and context for outsiders. Morris Chang is like Elon Musk here. The Chinese nickname for the company is literally translated as the Silicon sacred mountain or the Silicon shield.

Recently, I was in Kaohsiung, which is a city in Southern Taiwan. TSMC recently announced that they’re going to put a new fab there. I’m not quite sure what generation, but it’s not a leading one. It’s kind of the smaller ones. And all everyone could talk about in the cafes, at the conferences … I’m at Starbucks and there’s little ladies talking to it with their friends. At the startup festival I was attending, the keynote speaker was a member of the municipality. I was later told he was the mayor of Kaohsiung.

He came in and I didn’t understand what he said, because he spoke so fast and he spoke in really advanced Chinese. Except for them, he can say the Chinese name of TSMC, which is Taijidian, just kept saying, “Taijidian, Taijidian, Taijidian,” repeatedly, repeatedly. It was like some sort of cult chant. So it’s really hard for an outsider to understand how important TSMC is to Taiwan. Their new foundry in 2019 consumed the third of Taiwan’s entirely newly generated power that year.

There’s a generation of Taiwanese who are now rich because they bought TSMC stock. It wasn’t all to just one guy, one rich family. It was for the whole nation. The 40,000 plus employees in Taiwan, they contributed over 1% of all total newborns in Taiwan in 2019. So out of 23 million, all the newborns, one company. So I think it’s a really big deal. And it’s actually something really interesting to look at, and you get really involved and really immersed in it. And this company that almost no one really hears about outside the island and outside of when things go wrong, here, it’s a very big point.

Kalani Scarrott (03:44): That’s so cool. I never even thought about the cultural aspect of it. Everyone just thinks about the tech and the economics. But yeah, the cultural side is totally different. So for listeners, maybe to get a bit of background and understanding to what TSMC do, could you maybe explain the chip development process from start to finish? So maybe from the original idea all the way through ending up in our iPhones, I guess, could you maybe detail that?

Jon (Asianometry) (04:02): Yeah, so just get ready. You have four general stages: Design, fabrication, packaging, and testing. So design starts with a specification and you have a high-level design representation of your chip. And then that’s actually made up of integrating hundreds of a pre-designed and pre-verified hardware, IP course blocks. And these are provided by a whole ecosystem of industry players like OEMs, third party design houses or TSMC itself.

TSMC actually owns a large repo of IP property that it can license to you. You convert that into a net list, which is a bunch of gates. And then you route that using EDA software, meaning you actually draw the lines and stuff like that. You have your design. After you verify it, you transmit it to the foundry for fabrication. And we’ll talk about the fabrication a bit later. They’ll make the wafers over a span of four to six months.

After fabrication, the wafer is cut, packaged and tested, which means someone has to cut the wafer into chips and case them within ceramic or plastic to make it easier to handle, integrate them with other chips if necessary, and test them to ensure the quality. Test and assembly packaging are generally what we call the backend. It’s kind of like a repetitive work. It requires a lot of dexterity. It got a lot of close attention, which is why it tends to be outsourced. You have companies in Malaysia, for example, that that really do a lot of this. And once this package goes to the secondary vendors like Foxconn and stuff like that for putting into your iPhone.

Kalani Scarrott (05:36): So then for the science behind this, so TSMC is the first foundry who provide 7 nanometer and then 5 nanometer production capabilities. And then to put that into context, the human blood cell is about 2,500 nanometers and then a single drop of blood, there’s around 5 million red blood cells. So it’s a crazy small scale that they’re working at and it’s hard to even fathom.

So could you maybe set the scene for how technologically difficult and impressive the work that TSMC is doing, especially because sometimes it’s a little easy to get lost in the numbers, I guess?

Jon (Asianometry) (06:02): I think you shouldn’t think about it. What’s amazing about the work is the fact that it’s about really small nanometers or actually 2 to 5 nanometers, because that’s more of like a marketing. That’s a marketing number. And generally, the only goal is to say that it’s faster and faster than the chip before. Like a 5-nanometer chip is faster than a 7-nanometer chip. TSMC actually calls them like N5 or N3, N7 and so on. But it doesn’t mean that it’s any harder. Wafer manufacturing is really hard.

So to give you a good idea, they do it in the mask layers. A mask is to reproduce a pattern onto a substrate. So you put a whole chip pattern or part of a whole chip pattern onto one mask layer and we’re doing just part of a chip pattern that’s called multi patterning. So you’re using multiple masks to create just one whole layer. Each mask layer requires steps of 15 to 25 per mask layer.

So you might know some of those steps like lithography, but you also have oxidation, ion implantation, diffusion, chemical vapor deposition, a whole set of PhDs behind each one of those steps. So there can be up to 600 steps for a simple 180-nanometer process chip. That’s a chip from 20 years ago that has something like 20 layers or something. Today’s chips, which are N14, N16, N10 can go up to 60, 70, 80 mask layers. That’s how you get the more details, the more density just by adding in more mask layers.

But there’s an economic cost with that. Layers take more time to do and you don’t want to take too long to do your wafer because then your customers don’t get product in time. So you have to make sure that you’re not passing bad wafers to the customers. So that means you have to make sure that each one of those steps on those 400 steps, 600, 800 steps, each one of the steps have to have a really high yield almost. Even if it has a yield of 98%, the total yield out of your wafer with 400 steps is just 0.03%, which means you three good dies out of 10,000.

TSMC is historically known for very good yields. I was looking at that Canaan financial filings, the company that makes BTC miners. Their yields at 16 nanometers were 96% in 2017, 96% in 2018 and 95% in 2019. TSMC 16 nanometers has 60 wafer layers, which is about 800 to 1,200 steps. So you need better than 99.99% yield on each of those 800 steps.

So imagine doing something that succeeds 99.99 whatever percent of the time 800 times and doing it really fast too, like really fast, fast, fast. So I think that’s the impressive a part of it. It’s not necessary that we’re doing this nanolithography or something like that, it’s doing it for all these other companies at really accurately, really fast.

Kalani Scarrott (08:52): Yeah, that’s insane. We’re what, eight minutes in, my mind is already blown and gone into a tailspin. So where are they doing this then? You mentioned the fabs, what do they look like? Because this is where the magic happens. What’s the setup and the infrastructure that allows all this to happen?

Jon (Asianometry) (09:05): A fab is a factory just like any other. It’s a big, massive building with a clean room inside. It’s big. It’s really big. There are multiple fabs. TSMC is one to actually make chips. That’s the ones that everyone talks about. But the ones that do packaging, testing, R&D, we never hear about those. I actually was taking a vacation near a fab that just does, I think, packaging and I jogged around and it took 20 minutes to go around. And it literally doesn’t even do like their core thing.

Fabs are built in phases. You have phase one, phase two, phase three. So, usually when they quote the big cost numbers like 20 billion, 17 billion, they’re summing all the phases together. You don’t really do all that 17 billion all at once. Because you want to get your fab running in a year, you do your phase one. Then you do your phase two, then phase three.

You have to pre-plan all the layout, all the clean room, tell where all the equipment has to be, and it has to be done really fast because if you’re not doing it in a year, you’re losing and you need to be better. Your fabs are immensely expensive to build. They use a lot of water. They use a lot of power resources. All of those wirings need to be ready because you don’t want that to delay anything.

And then at the heart of it is you have your fab clean room. That’s like a massive building. That’s where all the equipment is, the lithography equipment is and stuff like that. Clean room size is directly correlated to the expense of the overall fab. So fab, to give you a sense how kind of massive and undertaking this is, a fab with clean room, just 8,000 square meters needs … I looked this up … enough concrete for 25 kilometers of road, 120 kilometers of ultra clean pipes, 250 kilometers of electric wire, 4,500 kilometers of steel bar.

It uses 24 swimming pools of ultra pure water each hour, though that gets recycled. It uses enough compressed air to fill 3,000 balloons each minute. It runs 24/7 all the time, night and day. And guess what, a TSMC giga fab has a clean room 13 times larger than that. Fab18 in Tainan where the N5 and N3 are being done is 20 times bigger, 160,000 square meters. And TSMC has six of those giga fabs, one in Nanjing, Jiangsu province in China.

Kalani Scarrott (11:19): Wow. These numbers just keep getting bigger and bigger, it’s insane. And you’ve mentioned that the semiconductor process is about as thirsty as a 16-year-old boy in Instagram. Why do they need so much water? And what are some problems that maybe arise from this thirst?

Jon (Asianometry) (11:30): It uses amount of water in all sorts of different things, mostly washing the wafers. You’re cooling the tools, you’re also doing that. You’re kind of cooling the environment, that all takes water. But most of it is using for washing the wafers. And you have to use something called ultra pure water, which has no particles of a certain size, which is defined as a killer particle.

And studies have shown that for a 300-millimeter wafer, which is about 12 inches, 12 killer particles is enough to affect its performance. And the definition of a killer particle has changed. It used to be 30 nanometers. Now, it’s 10 nanometers. A 10-nanometer particle is actually smaller than what existing metrology can test for today. So they’re actually going by theoreticals. Actually, it’s never exactly clear to me how they do it. I reckon it as a trade secret.

The more sophisticated the process, the more water it needs. So actually moving from 45 nanometers to 28 nanometers increase the water usage per unit by 30%. That’s partially because there’s more layers. They all need to get washed. After you do a chemical deposition or something like that, or you do lithography etching, you need to wash it away.

Historically, fabs have kind of focused on reducing the energy usage rather than the water usage, because the bean counters, the economics of it is very easy to correlate the amount of energy with the cost of the wafer. But with fabs getting larger and larger, the fresh water is important for city company relations and it’s really hard to disregard this. Even where there’s said to be a lot of water “available”, you can’t really scale to tens of thousands of wafers done each month. So recycling technologies have to be used.

And I read on a presentation that says that TSMC reuses each drop of water three and a half times. That technology, pressure came to them directly from the city of Tainan. So I think they consider it part of their corporate strategy. And I think it’s a really powerful, competitive advantage too.

Kalani Scarrott (13:26): Yeah, it’s interesting. And same thing for the fabs themselves, they’re getting bigger and more expensive. Is that just a function of demand or what’s driving that?

Jon (Asianometry) (13:35): I think like you would say, so you’re asking whether the fabs are getting bigger because of demand or is it because of something else, right?

Kalani Scarrott (13:42): Yeah, basically.

Jon (Asianometry) (13:43): I would say that it’s kind of a little bit of both. The key for TSMC is that they want their fabs to get bigger because of scale. It’s actually really simple. You have a big fab, big clean room, all this equipment sitting in there and there’s bottlenecks. Lithography is one bottleneck, but then ion implanters are a bottleneck too.

You put all that equipment in there. You’re moving the wafers through. They need to go through some of these sequentially. Some of it can be done in batches and stuff like that. And if something breaks down, if something takes longer, a giga fab, a bigger fab just has more equipment available to use.

So this actually scales to a really, really big size, which is why giga fabs have been able to just get bigger and bigger and bigger. There is an upper limit, of course, but we haven’t really figured that out. It really depends on your economic model. The key point, of course, is just making sure that you have enough demand to fill that. And that’s where big customers like Apple and such kind of step in as well.

Kalani Scarrott (14:46): Yeah, it’s perfect that you mentioned Apple because for the economics behind building the fabs, TSMC has gone to great lengths to sort of accommodate Apple’s product rollout, which is probably fair enough as they represent about a quarter of their income. So what do the economics and the numbers look like behind building a fab, especially when it’s often dedicated to a sole customer or a large portion of that customer? What’s that whole relationship look like?

Jon (Asianometry) (15:07): I think as soon as you finish building a fab, it starts depreciating. It’s like a car. As soon as it rolls off the lot, it’s starting to depreciate and lose value. 70% of the cost of a wafer is actually depreciation. As soon as you finish, the fab starts working and the capital inside is starting to depreciate and you need to basically pay that back.

With depreciation, it’s a counting metric that attempts to replicate the ongoing expense of maintenance. And that expense of CAPEX and all that is what kills foundries because that’s cash out the door that won’t get paid back later. So for TSMC to pour $9 billion to start a new fab for Apple, it’s a huge financial risk for the foundry to start any new fab, because there’s a chance they might not execute well and all that.

But I think it’s a financial risk that TSMC is actually willing to do. It’s actually kind of a slam dunk because how many partners are there that are like Apple. You have a partner that’s willing to work with you at the leading edge. GlobalFoundries really depended on AMD to kind of be their anchor customer, and Apple is far larger than AMD.

And now TSMC is starting to try to do the same for Intel. Apparently, they’re pouring billions of dollars to create a brand new fab for them. So it’s interesting to see how that relationship is going to turn out in the future as well.

Kalani Scarrott (16:24): Perfect. And I think that’s a good segue into maybe the competitors and the landscape of, I guess, the semiconductive business. So for TSMC, could you talk a little about their supply chain and their relationship maybe in regards, specifically with ASML? Are you worried about TSMC’s reliance and dependence on ASML, and maybe you should explain how that whole relationship works too.

Jon (Asianometry) (16:42): ASML and TSMC, they work really close together. They’ve worked together ever since ASML had been basically Philips. ASML exists now as kind of like a joint venture of Philips and ASM, but most of that have been Philips. You can’t do N7 like 7 nanometers without EUV or you can do it, but you can’t do it profitably.

It’s basically a science project and you can’t do N5 and so on at all without EUV. So I think there is a risk, yeah. But I feel like the terror case is like, if you can imagine what that worst case scenario is, it’s that the ASML decides that they will only sell to Intel, only sell to Samsung and not sell to TSMC. I feel like that’s not exactly going to happen unless there’s a geopolitical incident.

I guess there’s also a possibility that Canon or Nikon, like Nikon mostly will break through to EUV and they’ll do it better. But I also think TSMC is just as capable of switching suppliers, as you know, Intel did many years ago because Intel used to use a lot of the Japanese lithography machines too. And they switched over to ASML.

So there is that kind of dynamic there. And the two actually work really closely together. A lot of people just say the EUV machine comes in, they kind of imagine the EUV machine coming in like an Amazon box. You pull it out, it’s ready to go. The reality is it’s a bunch of modules and the TSMC and the foundry chooses the module and puts it together kind of how they imagine, how my best work for their particular … I guess, might even work for their particular layout of the clean room.

So, imagine don’t think of an EUV machine, think of an airplane. These are airplanes that are basically being built to fit and they’re being reasonably customized over time.

Kalani Scarrott (18:29): So forgive me if asking a dumb question, but how would you explain that TSMC adds value compared to ASML who just provides the machines? There’s a description that ASML sells the pots and TSMC sells the cooking. How accurate is that?

Jon (Asianometry) (18:43): I think it’s pretty … I don’t think it’s a dumb question. I get a lot of comments saying like ASML is a European company, and they’re the only ones making EUV, why are they selling it to TSMC? Why aren’t we making like a European fab that ASML can sell to? I think the answer is that lithography is by far the most expensive part of the process, but it’s not the only one.

I think the fallacy is presuming that the most expensive equipment is the most proportionately important one, this other equipment involved in the process and it needs to be source from all over. The wafers come from Japan, the masks come from Japan. The packaging services are in Taiwan, applied materials that’s the chemical vapor deposition, that comes out of the United States, Japan, I guess.

And all those companies need to be put together into basically, your restaurant, your kitchen. So just because the most important part, the oven is kind of being made in a certain place, it doesn’t really mean that TSMC is not giving any value here, it’s not doing any value, because this is really important to also be the cook.

Kalani Scarrott (19:43): How much are these machines again, just for context?

Jon (Asianometry) (19:45): I think your standard EUV machine is like 150 million and then you have the next generation high-NA EUV, which I covered in previous video, that’s hitting 300, 350 million.

Kalani Scarrott (19:59): Unreal. There’s a backlog of orders, I’m guessing, as well?

Jon (Asianometry) (20:02): I would say so. They’re trying to make as many as they can. I haven’t dived into the ASML documents yet. I was preparing for this TSMC deep dive, but I’ll probably say that a lot of these items take over a year to build. I think I said earlier that an ASML that a Carl Zeiss lens system, optic system takes over 18 months to build. So you can’t exactly ramp that up really fast.

The ASML is actually waiting for their suppliers to get the raw materials, to meet their requirements and all that, to get that done. So, yes, that is part of the backlog.

Kalani Scarrott (20:41): And for TSMC themselves recently announced a 44 billion CAPEX plan and competitors have announced similar spending plans. Is a glut inevitable in the semiconductor scene, I guess?

Jon (Asianometry) (20:51): Yeah. So like Intel did, they’re committing 20 billion to an Ohio site. There’s like a possible 100 billion commitment. I think it’s hard to not say we won’t be in a glut at some point, especially if the economy slows down and interest rates rise. That doesn’t really mean you guys are going to see cheaper GPUs. I keep getting comments about that.

I did a video about semiconductors in Northeast England, or Northern England. And I think that’s a pretty good show of what could happen, really go wrong when it goes wrong. The market just turns super fast just as the fab gets built, the tide goes out and you see the whole reason the fab existed was to soak up tax credits. For me, when I was working that video, the key point was technology. When the tide goes out, only the leading edge really survives.

I’m not going to say that’s what’s going to happen with this Ohio plant. I’m not saying this is going to happen to Arizona plant. The industry’s learned from what’s happened with these different companies. But I think TSMC generally sees the situation as a net benefit for them because they tend to want market share over profitability. They know that they have a really strong capital base. They know they can set the market on fire. They know they can take the heat. And when crashes happen, they tend to buy non-profitable capacity off their losers.

Kalani Scarrott (22:04): Is it naive to think that Intel, Samsung, other competitors can catch up just by spending the same amount as TSMC? How else can competitors catch up to them then?

Jon (Asianometry) (22:12): In the case of Intel, Intel hasn’t really competed with TSMC before. They’ve seen and actually played in different circles. Intel and TSMC have been actually quite friendly. Andy Grove was one of the Morris Chang’s first customers. And actually, Intel worked with TSMC to get over 200 different processes on their product right.

So generally, it’s sort of weird. Samsung’s always been TSMC’s biggest competitor. It’s been the company that’s been most willing to steal talent, like to really spend money. They’re really ambitious too, Samsung. They have explicit goals to kind of just spread out and take over everything. Taiwan used to have a substantial memory and display LCD panel business, Samsung took all of that away. That company has been investing since like the ’90s and they’re going to keep competing.

So, Intel, with their foundry thing, it’s hard to make sense of what to do about it until we start seeing revenue come into the books. If they break it out into a real segment and we start seeing it take share from TSMC and GlobalFoundries and Samsung, that we could look back and then say, “Wow, they weren’t talking out of their butts,” and it’s going to make me look really, really stupid, of course. So I say, never doubt a $7,500 billion company.

But right now, you can tick off a whole bunch of reasons why Intel’s foundry won’t work. The EDA tool integrations aren’t ready. Intel has generally done what’s done by itself. They squeeze a lot of their design-manufacturing integration. So are they the best GPU designer, the best CPU designer? Are they the best manufacturer? They need to be both now. Foundry is a service business, like Intel has never really done that sort of thing before.

Taiwan, their business culture is kind of Japanese that they really do customer service well, broad generalization. And then of course there’s like Intel is using TSMC’s N3 process. That seems to be almost confirmed by now. So, how can Intel sell foundry services with their customers while using another foundry for the leading edge?

I think what you can reckon is that Intel foundry ends up something like GlobalFoundries. So, losing a lot of money despite hundreds of millions of dollars of government subsidies, they’re selling wafers at a cheaper price because each year the competition comes up behind them. That’s one scenario.

And I think culture-wise, TSMC is this very aggressive company. You work really long hours and you work day and night. TSMC can get away with it because they pay pretty good, labor laws are pretty weak here. But also just like people work really hard for it because it’s TSMC. It’s the Silicon sacred mountain. And I don’t think Intel has that status in the United States.

Kalani Scarrott (24:47): That’s great. And for TSMC, obviously so closely tied with Taiwan, have they maybe got all their eggs in one basket? The China threat has obviously been talked about into the ground, but even another event like the 1999 Jiji earthquake could totally hold production. I know you’ve mentioned how the clean rooms are elevated at their fabs, but I don’t think it’s crazy to say that TSMC is probably the most important company in the global supply chain. So, how do they mitigate risks like that? Because they’re starting that smaller Arizona plant, what else, I guess?

Jon (Asianometry) (25:16): I want to start with kind of like the geopolitical risk because I’ve never really talked about the China thing in the Asianometry video before. It’s kind of like a black swan case. It’s like those nuclear missile drills that they make the kids do back in the ’70s or the ’60s. Covering your head with your hands is not going to help with nuclear fire. There’s no discount you can apply to the stock that codifies the risk of invasion.

And frankly, I think people, they shouldn’t think about in that way anyways, like TSMC is the least important part of the issue. And people need to stop thinking about that situation in the context of how much their next GPU costs. It’s stupid and insulting to the people who live in Taiwan, including myself. Your opinion on TSMC actually says more about who you are. Unless you are Joe Biden, then it’s more the reality.

So, for earthquakes, the company has put a lot of effort into kind of earthquake amelioration. They’re diversified across Taiwan. You got fabs and Taichung, Tainan, Kaohsiung, Miaoli, Baoshan now. Some of the worst earthquakes have been in Nantou, Yilan, and Hualien, so that’s kind of on the eastern side of the island. And they’re doing a lot of technical things like they’re really sharing their patents and stuff like that. But the reality is you can’t really do anything about it.

They’re fine for something up to like 8.0 or something like that, but nothing can be really done about something that’s already off the charts. That’s sort of something that’s just going to hang. And I don’t really think a fab in the United States ameliorates for that risk because if you do the math, it just doesn’t work out. TSMC’s fabs are doing 10 million wafers a year. Two or three more fabs in Texas, Ohio, and Arizona, maybe they do 50,000 wafers or something like that. That’s not enough. Lot of this equipment does not make sense unless it’s being used 100% of the time, like really isn’t.

Kalani Scarrott (27:05): To go back to TSMC and their customers, is Apple being their biggest customer at risk because they obviously work so closely together? And whilst building a fab is a massive investment and technically very difficult, Apple is maybe one of the few companies with the resources to do so. Are you worried about that? Do you ever think about that?

Jon (Asianometry) (27:22): I’d say it’s a really big risk. I think Apple anchors TSMC’s customer base. Without Apple, I don’t think TSMC gets to be the giant that it is today. So, yes, there is a failure mode where Apple one day announced they will second source M1 chips from Samsung or Intel, then TSMC stock is going to take a massive hit. I think losing any one of the core customers like AMD, Nvidia, Qualcomm, MTK MediaTek will hit the stock pretty hard, but Apple most of all.

That being said, I think Apple and TSMC work really closely together, and it’s really hard to step off that treadmill when you’re on it. Apple and TSMC get to work together and define their process development kit, the PDK. It’s called Design Technology Co-Optimization. It’s really, really tight. Literally, the TSMC engineers will tell Apple engineers, you can’t arrange these logic gates this way because it’s not going to project, it’s not going to yield. The Apple engineers will say we will redraw the gates elsewhere.

So I think it has to be something kind of really bad to happen before that failure mode sort of happens. In fact, we’ve seen that TSMC’s N3 missed the two-year window to get for the iPhone and maybe even the iPad and Apple is still working with TSMC here. So, I think they’re working really closely together and it’s going to be hard to kind of separate them.

I don’t think Apple can build their own semiconductor fabs. They’re kind of already moving beyond that. They’re kind of moving towards the system integrator of Boeing model where they’re accurately picking and choosing suppliers and interesting technologies to integrate into their systems.

I think it’s going to be interesting to see though kind of spinning off of that. It’s like TSMC has been looking for another client that’s sitting alongside Apple at the leading edge. And that used to be Huawei, but Huawei got booted. I reckon it’s going to be … It looks like right now, it’s going to be Intel.

So, it’s interesting because Apple is not going to leave. I don’t think Apple will leave TSMC because of Intel. Because Apple was competing head on with Huawei, they didn’t leave TSMC then. But maybe AMD will lower their business with TSMC because of it. AMD and Samsung worked together for an Exynos chip, and I think that was pretty interesting. And it makes me wonder kind of which came first.

So, I think TSMC is going to play AMD and Intel off each other for a little bit. So that’s going to be really interesting to watch in the years coming forward.

Kalani Scarrott (29:42): Spicy. Interesting. I know you have strong feelings about this because you’ve mentioned it in a previous video, but I got to ask a silly question because I don’t want listeners to come back and turn around to me later and ask. But why doesn’t Apple just buy TSMC?

Jon (Asianometry) (29:56): I wrote about it back then and it was even more so the case now. TSMC back them was only $350 billion. Now, it’s $650 billion. So, Apple really doesn’t have the money now. And secondly, it’s going to … Basically, they would put Apple or TSMC in competition with all these other customers like Intel, for instance. Intel, I think, will never work with all these companies now. Qualcomm, for sure. So, you’re destroying value.

And lastly, Taiwan government will never let it happen. I spoke earlier about how passionate Taiwan is about TSMC. They’re never going to let control be handed over at any cost. It’s crazy. It’s crazy to think about it, and even crazier now.

Kalani Scarrott (30:43): No, I bet. So maybe to bring TSMC to the current day and their future plans, could you talk a little bit about their Q4 results and what this means both now and maybe for the future?

Jon (Asianometry) (30:54): Because I was looking at TSMC, I was thinking about how highly valued. It was really strange. It’s like the eighth or ninth most valuable company in the world. It’s the biggest non-government owned non-American company in the world. It’s $650 billion and it’s kind of why. You’re kind of wondering why because it doesn’t really make as much as like an Exxon or a Walmart. And the profit is far less than like an Apple or whatever.

So I had some thoughts. I was thinking about it. It was like the company is simple to value. Maybe it’s simple to predict the revenues. They perceive it to have scale, which it does and they perceive it to have a monopoly, which I probably don’t think it will, it does. I thought maybe also could be kind of like a quirk of the market. Everyone in Taiwan buys TSMC stock and they never sell. If you think Bitcoin is full of holds, you’ve seen Taiwanese aunties, they hold this stuff for years.

I was listening to the Q4 call and there’s this really smart analyst called Sebastian. That’s the name of my sister’s cat, and he pointed this out. There’s something really interesting happening with TSMC’s CAPEX and their future revenue. If you take the CAPEX for a year, multiply it by about three times, you can broadly predict revenues for the next year. And it makes sense generally because it generally takes a fab a year to get on track. So this trend has been going on basically for a decade.

In 2014, they spent $10 billion in CAPEX. A year later in 2015, they generate $30 billion revenue. 2019, they spent $16.6 billion in CAPEX, they generated $48.4 billion in revenues a year later, 2020. 2020, they spent $18.3 billion CAPEX. In 2021, they generate $56.8 billion. So in 2021, TSMC spent $30 billion in CAPEX. So does that mean in 2022, TSMC is going to make $90 billion in revenue? So, I’ve seen other conservative estimates saying like $72 billion and even their financial projections say its CAGR is going to be 10% to 15%.

But let’s say the three times does hold, they make $90 billion in revenue. At 38% net profit margin, that’s $34 billion in net profit. That’s ExxonMobil in 2003. That’s Google/Alphabet in 2019. And the even crazier thing is like 2022, TSMC says they’re going to spend 40 to 44 billion dollars. So if they hit the high case for that CAPEX, does that mean like in 2023 is TSMC going to make $130 billion in revenue? And if you still have that same net profit margin, that’s $53 billion in profit. That’s more than Microsoft in 2020 and the same as Apple in 2020.

So, it’s kind of mind blowing. That basically means at a 20 times PE that’s a trillion dollar company, and I think that’s insane. That’s insane. And I actually don’t believe it’s true. It can’t be true, like I refuse to believe it’s true. So let’s say we compress the multiple, but still means this is an 800 to 900 billion-dollar company. It’s crazy.

So I think maybe the reason why this company is so highly valued is because it’s actually quite simple. It’s a very conservative company. It’s very simple to understand. It’s very transparent. Revenues are reported each month, and this leading indicator that’s used, that’s worked for nine past years is flashing this utterly insane amount of growth. It’s crazy.

And especially considering that this is not a software company, this is a hardware company making things. Their past 10-year revenue CAGR was 14%. Over the last 10 years, they’ve grown revenue by 14%. They’re saying like long term, next several years, they’re going to expect their revenue to be 15% to 20% CAGR. That’s crazy. Even larger base, even faster. They’re going to grow even faster than that, which is really interesting.

Kalani Scarrott (34:41): Yeah. There’s so many points there because it’s the growth on an already large base number. And then even just the margins for a hardware business, they’re unheard of. There’s just so many factors going for it. And it’s maybe a bit of a story as well because the strategic importance and the digital transition, everyone just loves that story. And TSMC is leading the way, I guess.

Jon (Asianometry) (34:58): Yeah. And it says like they have, what, 50% market share, 57% right now, which is more than they traditionally target, which basically means if you think about it, the fabulous market is TSMC. So that’s telling you that the industry is going to grow even just as fast. People are estimating … I read this article somewhere that says like the fabulous companies, their revenue estimates are way too low.

If you look at how TSMC is looking at, TSMC is projecting this sort of growth and fabulous companies are projecting like 9%, you need to revise those up. Nvidia, AMD, all these companies, they’re going to grow much faster than you think.

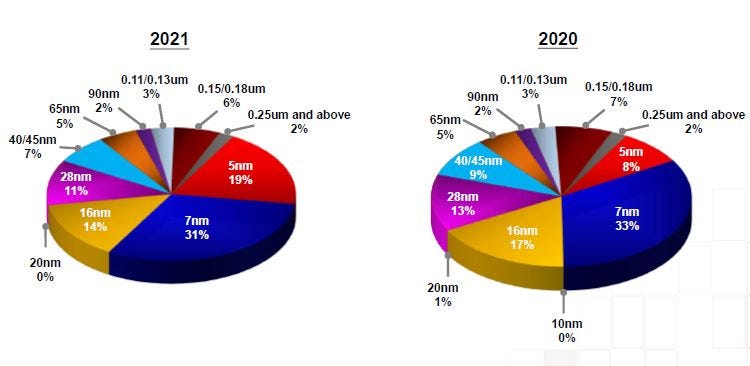

Kalani Scarrott (35:40): And even you mentioned that 57% market share, TSMC has a higher percentage of the higher-end as well.

Jon (Asianometry) (35:46): I think it’s like 95%, yeah.

Kalani Scarrott (35:48): Wow, crazy. Damn, where to now? So you’ve mentioned before in one of your videos that TSMC is very open except when it comes to their fabs. And when you compare this to ASML who’s extremely open with their research findings, is there any theories as to why TSMC is so secretive when it comes to their fabs specifically?

Jon (Asianometry) (36:07): Yeah. I think ASML is very open with their conceptual research, but they’re never going to tell you how they actually put it together. That’s like the trade secret is. And sometimes, this stuff is just too hard. Optics, I think only 10 people really know this stuff. TSMC is kind of like a very conceptually simple company, so their trade secret is their fab. And it used to be, actually you could read whitepapers about how their fab is laid out, how the automated system works, what they focus on. You can see kind of what they’re thinking about when it comes to the recipes.

But in, I would say, 2008, 2009, they had a really kind of a big stumble. Samsung and SMIC kind of just came in and really took their lunch. They just grabbed all of their trade secrets and really used to catch up to them. So I think it caught them very nasty lesson about what it means to be too open. I don’t think you’re going to find anything about their operations or work styles past 2010.

The best thing of recent kind of providence I can find is there’s this article in the CommonWealth and it’s like a news business magazine in Taiwan. And it discusses how the fabs are more automated than ever before. They’re using these large data sets to optimize recipes, operations, how they’re doing the recipes, and a lot of these machine learning models. No one knows how it works.

So I guess it kind of makes sense to me that we don’t hear about how TSMC works and optimizes because nobody really knows. It’s really data driven, and they can do that because they have scale that no one else does.

Kalani Scarrott (37:37): Damn. If the US wants to compete generally in the semiconductor business, is the talent hurdle just too high and the knowledge barrier just insurmountable? Because if 10 people running the optics at ASML, then what chances the US have? How do you think about that maybe?

Jon (Asianometry) (37:53): I don’t think it’s impossible. I have this story here, this is a cute one. I don’t know if it’s true. But long ago, Singapore’s founding prime minister, Lee Kuan Yew, visited their national champion foundry, Chartered Semiconductor. Chartered’s management team showed them the chips and the progress they made over the past few years, and Lee asked them, how far away are we from Taiwan? They replied five plus years. And Lee said, “Just buy from them.”

I think it’s hard to catch up to the leading edge once you stop going for it. But because the new leader is moving as fast as they’re moving, if you want to catch up the leader, you have to run faster than them. And also because it’s really easy and more financially profitable … And the second part’s actually more important … that’s more financially profitable to just say, “This is too hard and we don’t need a faster chip.” When it comes to semiconductor manufacturing, you’re not just racing on a technical basis, you have to do it on the economic basis too. If you do stuff in a lab, that’s nothing because you need to do it for customers at scale at a profit.

And I think like advanced manufacturing, that is very hard and it needs scale. It’s not talent. It’s about scale and capital. The more scale that TSMC gets, the more capital they’re accumulating, the better it gets at manufacturing, which means their customers get faster chips at a cheaper price. And I think this goes back to owning TSMC stock. Hypercompetitive manufacturing is a bad business. It’s horrible. I speak from experience. You do a massive hit video and then I’m like, “Wow.” Now, I got to make another. It would be nice if I had a newsletter subscription like Ben Thompson and just sit back and collect checks each month.

So, these TSMC engineers ramp up N7 and now they got to do N5 and then N3 and then N2 and whatever comes next. There’s no D to C subscription for semiconductor manufacturing. And if you’re not at the leading edge, then the Koreans will catch up and the Chinese will catch up. If I’m Nvidia, if I’m IBM, if I’m all these other companies, why deal with that? You take the higher margins by being a fabulous company and move on. Why do you think all these tech companies are going to D to C subscriptions? It’s crazy.

Kalani Scarrott (40:15): No, Fair enough. I don’t know if this is a dumb question, feel free to ignore it. Is Moore’s law really dead then? Is it too hard to just keep that, I don’t know, ball rolling?

Jon (Asianometry) (40:25): Moore’s law was never like a law. It’s a pace setter. It’s like those electric rabbits in a dog race and a greyhound race. It’s a pace setter for the industry to continue pushing technological progress forward, but it’s getting harder. I think it’s interesting to see then like in 2000, 2001, the return on investment for capital buildup in the semiconductor industry overall started to decline. Total assets kind of peaked, and it sort of stayed stagnant for a couple years.

And I think part of that is because the dot-com bubble popped. But also second is because you had this generational change where you went from kind of KrF lasers, DV machines to 193 nanometer ArF lasers. And that was like a generational change that shook out so many customers because suddenly, the lasers are so much more expensive.

But the semiconductor space is so rich and there’s so much money in it that you can just throw smart people and money at a problem until it goes away. For the first 30, 40 years of the industry, the pathway to a faster chip was simple. You need more transistors, you need more gates. And so, you just squeeze the gates together more and more and you do that for 20, 30 years.

But around the 32 nanometer node, that stopped being the case. So the scientist was like, “All right, we need to make better gates rather than denser gates.” So they introduced this concept called FinFET, and N22 and N16. At the same time, laser lithography got hard because even 193 started become insufficient and EUV was delayed. So they keep doing 193 over and over again, so you have two, three, four, five, six times of 193 until EUV came about.

So I think semiconductor, the industry drives forward not necessarily because some dude 45 years ago said so, but because people want faster, better-looking games, because software programmers write crappy software and they just assume the chips will get faster and can run it, and because everyone’s working on the cloud, like so on. So long as the market is going to reward an electronics product for being better, the semiconductor industry is going to push forward.

Kalani Scarrott (42:33): Is there anything we haven’t talked about that’s consequential about TSMC’s future in your opinion?

Jon (Asianometry) (42:38): I think the relationship between TSMC and the Taiwan government is really interesting. The government owns a significant share of TSMC and sometimes gets involved in its operations. I think that’s why TSMC is building a joint plant with Sony and Japan. I know it’s definitely why TSMC is building that plant in Kaohsiung. We know that the Tsai administration got involved to help TSMC decide to put a plant there.

But I also know that TSMC, the government bends over for them too, like the R&D center sources new technologies, there’s new tax benefits for the employees and the companies. It’s really interesting to kind of look at that sort of interplay between the two because there’s give and take. I think that’s really fascinating and you never really see it on the surface.

And then the second thing I think is really interesting. I think the weird thing about this recent growth explosion for TSMC is that no one’s quite yet clear on where the industry growth is coming from. Abstractly, you can say like this is from AI, from high-performance computing, it’s data centers. But a lot of this stuff has been around for a couple years now, and a lot of these chips that are missing in the chip shortage are not that sophisticated. It’s like the 22, it’s the 16s, it’s the lower trailing nodes.

So I’ve been thinking a lot about this. It’s like where is this growth coming from? And no one’s quite been able to really … I guess TSMC probably knows. But no one else seems to really know where is this growth coming from. It’s a weird thing. It’s something I’ve been thinking about.

Kalani Scarrott (44:12): Do you think it’s maybe something specific or maybe just a broad range of demand goes up everywhere and everything?

Jon (Asianometry) (44:18): It has to be that, it has to be like a broad thing. It has to be. The numbers are basically saying that TSMC is going to be a $130 billion company by 2023. That can’t be just one company. That can’t be just Intel coming on board. That’s something else across that’s a rising tide. It’s so weird. I can’t really explain it. It’s bizarre.

Kalani Scarrott (44:43): Yeah. Fair enough. Either way, Jon from Asianometry, thank you so much for this deep dive on TSMC. My brain’s going to be spinning for a while, but cheers.

Jon (Asianometry) (44:51): Thank you so much. Thank you for having me.

Great content Kalani. I know it's been a while, but you should jump on The Closingbell Show to discuss! We have 60,000+ in our community who'd love to learn from you. We recently had on Alex Morris, Ayesha Tariq and Tyler Okland :)