Discover more from Compounding Curiosity

ASML - "The Most Important Company You've Never Heard of"

The Dutch firm makes the EUV machines that make semiconductors. Each machine costs $150m+, and they can only build ~50 high-end EUV machines per year.

So my guest to chat everything ASML and EUV is none other than Jon from

We chat:

🤑 ASML's relationship with their supplies

🔬 The insane science and tech behind an EUV machine

🌏 ASML's and EUV's impact on the global economy

Bloody fun episode, and bloody valuable too! Also my 50th episode of Compounding Curiosity! Incredibly grateful to have made it this far and to share it with a friend like Jon. So please enjoy this deep dive on ASML & EUV Lithography with Jon from Asianometry!

Listen to this episode on Apple Podcasts, Spotify, Stitcher, Castbox, Google Podcasts, or on your favourite podcast platform.

My takeaways and lessons:

Good luck if you want to make your own EUV machine

“I estimated it’d probably take some, probably about 15 years for a company to go from scratch to an EUV machine that’s probably workable and something along the lines of 10 billion dollars. […] And that was one of the issues that caused Nikon to drop it. No one else would use this.Energy - The Elixir of EUV

“The reason why they’re so expensive is because ASML’s been working on them for several decades. There’s all that depreciation cost they have to pay for, but also that they’re incredibly energy hungry. It’s estimated that one EUV machine uses as much energy as 10 DEUV machines. TSMC has one fab that they’ve been doing a long time in Tainan, and that single fab is estimated to use as much energy as the entire country of Costa Rica. And one year of operations will light up the Eiffel Tower for 17,000 years. So that’s part of the reason why these machines not only cost so much to build, but also cost so much to run.As Arnold would say - MORE ENERGY!1

“what can they do to fix this power consumption problem? Cause this power consumption of these EUV machines basically makes EUV unacceptable for vast number of companies, right? 6% of Taiwan’s entire energy consumption is basically to TSMC. A single company. And that goes up higher every time they buy a new EUV machine. I’m very curious and I think a lot about what ASML can do to reduce the power consumption on these machines. Especially when you get to even more advanced products and what consequences will that have for the chips themselves too. That’s more of a TSMC thing, but it is very curious to me.Maybe relax on the hype for advanced semis?

“I don’t think the world economy (right now) is that dependent on advanced semiconductors. Right? […] They’re seen as, almost like a pathway to a better future in some way. It’s like your option for a better future. In reality, what I’ve noticed is that the majority of semiconductors that actually run your life are very small, are very old, and very just normal. There are 200 fabs around this world, and many of them I think are of those types. You don’t really notice them. They’re quite small and they just churn out and they make money.“Why can’t ASML compete with TSMC?”

“just because lithography is the most charismatic, the most popular part, the one everyone thinks about semiconductor manufacturing, it’s not the only one. There’s other things like etching, deposition, packaging, testing, All those parts have to be integrated into the clean room when TSMC makes those chips. […] TSMC doesn’t know how to build a machine. ASML doesn’t know how to use that machine along with all the other machines that need to be used to make a full chip. And I also think, it’s unlikely that ASML will make their money back if they’re not selling to other clients. If they decide to go and compete with their own customers, they’re not gonna make their money back.A glimpse of the future

“you’re gonna see a possible de-emphasis on lithography and more emphasis on other parts of the manufacturing process like etching, deposition, but also packaging as well. I think it’s a challenge for ASML because they’ve staked a whole lot on lithography, right. And they’ve sucked out a lot of the investment of that industry, and if they cannot continue to bring down more economic, viable lithography machines down the line, that money, that investment still needs to go somewhere. And so you’re starting to see, you know, you have, you have situation when you see something like TSMC and they’re doing a lot of their advanced packaging in the house.

Mentioned/Recommended Content:

Show Notes:

[00:00:31] - [First question] - What is EUV lithography, how does it work, and why is it important?

[00:06:14] - Who is ASML?

[00:07:49] - Can other companies make EUV machines? How big is that jump?

[00:11:17] - Describing the insanity of ASML’s EUV machines

[00:14:21] - ASML’s relationship with suppliers

[00:16:13] - ASML and vertical integration? Can they become a fab?

[00:18:06] - Is de-globalization a threat to ASML's asset-light model?

[00:18:43] - Why zero defectivity is one of EUV lithography’s key challenges to overcome

[00:21:46] - The insane mirrors in an EUV machine

[00:23:22] - Can we even build a simpler, cheaper EV machine?

[00:25:20] - What’s next after EUV?

[00:27:52] - What kind of threat is the emergence of 3D DRAM that places more emphasis on itching and other processes rather than lithography?

[00:31:40] - The power consumption problem for EUV machines

[00:32:52] - Talking about the insanity of TSMC’s fabs

[00:34:42] - Does it worry Jon how much of the world economy is dependent on so few companies? [00:37:53] - Wrapping up

Connect with Jon from Asianometry:

Transcript

Kalani Scarrott: [00:00:31] Okay. How are we? My very special guest today is Jon from Asianometry, creator of the hugely popular Asianometry YouTube channel, where he posts video essays on business, economics and history within Asia. But in today’s conversation, we cover EUV lithography ASML, and everything in between from how it all works to the impact on the world and what it all means.

[00:00:54] So an extremely valuable and important conversation and one I’m extremely proud of and happy to share with you. So please enjoy my conversation with Jon from Asianometry. Oh boy. Jon, thank you so much for coming on today. A big topic, very in-depth. You might need to hold my hand a little bit, but we’ll start broadly, start easy, maybe just with EUV and then we’ll get deeper in the weeds on the technology.

[00:01:17] And then ASML. So broadly, do you just wanna talk about what is EUV lithography, how does it work? Why is it important? And um, yeah. Cheers to coming on too.

Jon (Asianometry): [00:01:25] Yeah, yeah. Yeah. I’m glad to be back on for the third time. To Compounding Curiosity, let’s start with kind of discussing why EUV matters, right? EUV is the continuation of a lithography trend that’s been going on for half a century, I would say.

[00:01:42] So in the 1960s when we printed semiconductors, we used a essentially screen printing techniques. This was basically what you would use to print anything really. You started with the drawing of your chip design, right? It’d be hand drawn and then you’d carve it onto this red tape called Rubylith, and you’d be standing on, actually, you wouldn’t be using like sharp shoes or anything.

[00:02:03] You actually use your socks and just cut this up yourself. The finished product was called an artwork, and you use that to create a photo mask. The photo mask is shrunk down 10 times using a special camera, and then it’s printed onto the wafer using something called like a, it kind of looks like a photocopier, I would say.

[00:02:22] And this photocopier uses light to transfer the chip design pattern, on the photo mask onto the wafer. So we coat the wafer using something called a photoresist, and that’s a special chemical that reacts to the light coming to the machine. and the machine that actually flashes a light is called your exposure tool.

[00:02:40] And so back then when we had contact printing, it really is kind of imagined like a photocopier. You press the mask hard against the wafer and then you flash it with light. And the the resist is left with like the imprint of the chip design. and back then we could flash the whole wafer at a time, which is just called the mask.

[00:02:56] Nowadays you have the more subtle changes which we’ll talk about later. now we can use this kind of, you know, flashed photo resist in the wafer as your stencil for etching processes down the line. This is where we actually etched the design permanently into the wafer substrate. So those were the basic early principles of lithography.

[00:03:17] That was the 1960s. That was like 60 years ago. That’s crazy. And so people found was that when you got smaller and smaller designs, you wanted to get smaller and smaller wavelengths. Right. if you think about it as like a chisel, right? If you want to chisel and etch lines that are an inch thick, it’s harder to do that.

[00:03:34] If your chisel is two inches thick, we want a smaller chisel. So, you know, back in 1980 Uh, we had something called a 435 nanometer wavelengths, mercury arc, G line lamps, and that was fine because the leading edge process node in 1980 was 1.5 micrometers or 1,500 nanometers. So you can see 1,500 nanometers with a 435 nanometers chisel.

[00:04:00] Yep. Super easy. but Moore’s law meant that, the Industry kept shrinking the nodes right, and the feature sizes they had to etch at. So from 1987 to 1999, bleeding edge went from 800 nanometers to 180 nanometers and 435 nanometers no longer was good enough. So they switched to eyeline lamps, which is eye line referring to a type of light.

[00:04:22] And that light had a 365 nanometer wavelength. But you know, Moores all kept going and kept going. So by 1999, they’re used, they switched to a 248 nanometer Krypton fluoride lasers for the 180 nanometer process, which is leading edge at the time. Two years later, they switch again to 248 to 193.

[00:04:41] Argon, Fluoride. So, you know, they all thought about what was gonna happen after this because, you know, the Moore’s law meant that the process nodes kept getting smaller and smaller and smaller, and you’re running out of wavelengths. So they thought about, going to a more disruptive type of lithography, which, you know, at first it was, well, they’ve looked at it another, at a variety, which we’ll talk about later.

[00:05:05] And then they said, one of the first ones they looked at like 157 nanometer, which is kind of like a bridge. And then finally they decide to do immersion lithography, where they send 193 nanometer light through pure water. but ultimately, what was the, the end goal that people wanted to do?

[00:05:21] They wanted to go from 193 to 13.5, so essentially X-rays, and that’s what EUV is. It is essentially the continuation of this kind of 60 year lithography trend where it’s the smallest possible chisel that can possibly have.

[00:05:35] Kalani Scarrott: And the jump from DUV to EUV, was that an extreme jump or

[00:05:40] Jon (Asianometry):It was a pretty, it was a pretty extreme jump, I would say.

[00:05:43] It’s very, it’s, there’s a lot of engineering because all the principles that while the, overarching principle of EUV remains the same. You’re using light to make designs on a wafer. the mechanism through which you generate and focus and bring that light to the wafer changed a lot.

[00:06:02] Kalani Scarrott: And the margins for error are incredibly small. With all this as well, cause since they are working in such tiny details.

[00:06:08] Jon (Asianometry): yeah. That’s always the case, but like, particularly yes, with EUV it’s very, it’s fun stuff.

[00:06:14] Kalani Scarrott: Scary stuff! For me, trying to get my head around it and listening to you. Oh my God, I’m just trying to keep up, But it’s so cool.

[00:06:19] So you wanna quickly explain and give a brief overview of who ASML is now and then why they’re so important in the whole factor of the world? I guess

[00:06:26] Jon (Asianometry): ASML is a kind of a joint venture company that exists, after their joint venture of ASM and, used to be like a, a unit of Phillips and so

[00:06:38] they struggled through the seventies and eighties because they were going against the, the Japanese photography companies, right? So the Japanese photography companies, Nikon, Canon had really dominated the American semiconductor, uh, manufacturing lithography, providers.

[00:06:54] They were for reasons, really tied into process to tied into, you know, overinvestment in the space, and also their own technical competency. So, ASML came up in a time when they were competing against Nikon and Canon. And one of the reasons that they became leaders in the Lithography field was that they jumped onto what I called before the 193 I nanometer light, and they were, one of the first companies to bring that to the market.

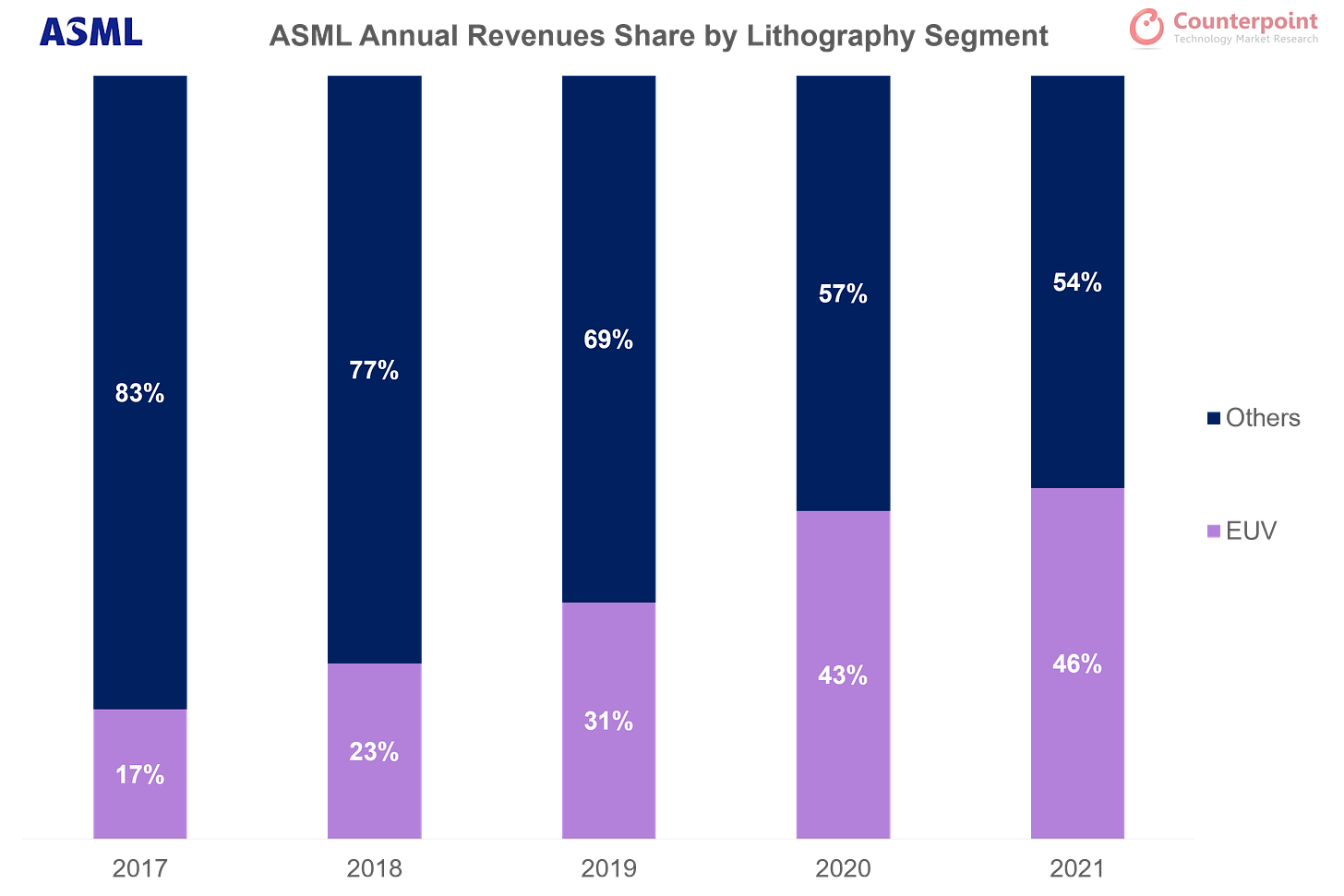

[00:07:22] They brought it faster than Canon and Nikon, and all this other time they’re also developing EUV as well. But one of the reasons why they surged forward, and became, what I would say a leader in lithography was, was the 193 immersion.

[00:07:37] Kalani Scarrott: And do ASML, is this right? They are the only supplier of EUV machines?

[00:07:43] Jon (Asianometry): They are the only commercial supplier of EUV machines. Correct. They, they’re not the only ones that have tried to make it.

[00:07:49] Kalani Scarrott: Do you see other companies being able to make it as well, or how big is that jump for them as well?

[00:07:52] Jon (Asianometry): That’s an interesting question. I think it’s like, um, well, we can, we can discuss, like, we’ll talk a little bit about how EUV developed as a technology and why ASML came into play.

[00:08:02] So like, EUV itself, the technology, the notion of using x essentially x-rays to develop, a chip pattern was demonstrated in 1986 and it was actually demonstrated in Japan, at a telecom company, NTT, their R&D lab. Right. And the Department of Energy kind of, they reads this document and they’re, they’re always looking for kind of the next generation of Lithography, technology department energy funds, a team to get some basic stuff to fiddle with, kind of to get a tool working right.

[00:08:32] And at this time,EUV was just one of many next-generation lithography technologies. You have electron beam, direct right, Proximity X ray, 157 as I mentioned, so all those other things. So EUV wasn’t particularly well reviewed, I would say. in 1997, Intel comes along, they see this new EUV tech and they like it, and they forward some funding, like 60 million or something to keep the team together, and then they work together with the rest of the American semiconductor manufacturers to create EUV LLC.

[00:09:03] A consortium to fund the basic technology work, So they get around 80% of the work done. They have just a tool. They have procedures, they know how to do it, but the 20%, you know, they leave they know the 20% to the industry. Well, of course, the last 20% is the hardest part. so ASML had joined EUV LLC with American permission because they acquired a company called, Silicon Valley Group Lithography.

[00:09:28] and there, like I said, there was no American lithography companies at the time because the Japanese basically wiped the floor with the industry in the eighties, but Japan actually was also in the picture. Nikon and Canon were not allowed to join EUV LLC because of geopolitics and, competition at the time.

[00:09:47] But they were allowed to attend the meetings. They were allowed to receive information, and they were very sophisticated themselves. I mean,, they had a lot of government funding. So, you know, for a few years in, into the 2000’s, ASML and Nikon in Canon were all competing to build the first viable EUV machine.

[00:10:03] And I think at the end, after the global financial crisis. Intel chose ASML, like the ASML solution. Canon dropped out pretty quickly, but Nikon kind of moved on and they actually had developed a working test tool, a completely finished, or not completely finished, but it was a, it was a tool that worked.

[00:10:22] there were some significant issues with it, but it worked and it was probably the most sophisticated lithography tool in Asia. but you know, after the global financial crisis, Intel decided to choose one. They went with ASML and then Nikon, dropped their product. All in all, I would say Nikon and Canon spent about, and Japan in general spent about 10 to 15 years on their own product.

[00:10:44] Uh, I would say 10 years. More like 10 years. And they invested something like 5 billion, five to 10 billion. I you know, I estimated it’d probably take some, probably about 15 years for a company to go from scratch to an EUV machine that’s probably workable and something in the lines of 10 billion dollars.

[00:11:06] Kalani Scarrott: Wow! And that’s what I mean, it might not even be financially viable to make it worth it all that time and effort.

[00:11:11] Jon (Asianometry): Correct. And that’s, that’s one of the, that was one of the issues that caused Nikon to drop it. No one else would use this.

[00:11:17] Kalani Scarrott: Wow. Wow. Okay. Let’s talk about the insanity of the machines. So given how important ASL machines are, yet they can only make 50 high-end EUV machines per year. So could you talk about the insanity that is $150 million lithography machines and, um, yeah. What makes them so expensive? I guess.

[00:11:31] Jon (Asianometry): they are very over-engineered and part of the reasons why they’re so over-engineered is because they were supposed to hit a certain, process note back in, I would say the mid two thousands. But that changed. they came across issues with effectivity, with the issues with the light source and whatnot.

[00:11:48] And then as this kept pushing, what happened was the process node that EUV needed to enter kept getting higher and higher. So EUV eventually hit that seven nanometer mark. That basically requires a very powerful light source. and so part of the reason why EUV machines are crazy over engineers is because they have to generate so much power.

[00:12:10] And the reason why they’re so expensive is because ASML’s been working on them for several decades. There’s all that depreciation cost they have to pay for, but also that they’re incredibly energy hungry. It’s estimated that one EUV machine uses as much energy as 10 DUV machines. yeah. TSMC has one fab that they’ve been doing a long time in Tainan, and that single fabs estimated to use as much energy as the entire country of Costa Rica.

[00:12:34] and one year of operations will light up the Eiffel Tower for 17,000 years. So that’s part of the reason why these machines not only cost so much to build, but also cost so much to run.

[00:12:48] Kalani Scarrott: And we haven’t even talked about setting up and logistics. So in your TSMC deep dive last year, with me, you said a lot of people just kind of imagine the EUV machine coming in like an Amazon box.

[00:12:57] You pull it out, it’s ready to go. But the reality is there’s a bunch of modules that the TSMC and the Foundry chooses the module and puts it together how they imagine how it best work in particular. So, um, yeah. What are some of the logistics behind installing an EUV machine? You can’t just buy it.

[00:13:10] Jon (Asianometry):

[00:13:10] Yeah, it’s kind of crazy. I mean, I think a lot of people ask me this, like, why is it like about the difficulties it all brings, and I’ve asked this. I’ve asked multiple people this including people who work at ASML, and unfortunately it’s not as, it’s not as exciting. I mean, they break it down into, into parts and they, they fly it over

[00:13:28] So it’s, it’s not exactly, it’s not like, it’s not like that time UPS shipped like a whale shark to the Georgia Aquarium. So it’s like, in this case, this EUV machine once it arrives, They, they, they truck it in and they install it. I mean, I, I wish I could say something more excited than that.

[00:13:43] it’s disappointing to a lot of people when they hear it.

[00:13:45] Kalani Scarrott: There are a few engineers and stuff that hang around and make sure the setup’s right. Is that right?

[00:13:49] Jon (Asianometry): Yeah, yeah. Yeah. I think as ASML has, actually when I was there at TSMC’S Tainan in the South, basically you see. TSMC’s fabs, UMC fabs, all that other, and then you see kind of all their suppliers too.

[00:14:02] You have applied materials. They have a very large facility there. ASML is one of their larger R&D locations are actually in Taiwan. And basically, they’re in one big building in Tainan too. It’s, it’s really interesting how kind of they actually have to kind of build there to, to get things going.

[00:14:21] Kalani Scarrott: Yeah. And on the topic of suppliers, I saw in your video you mentioned that ASML is kind of like a Boeing or an Airbus in that they collect a lot of different suppliers to make their parts and don’t do it in-house. So with ASML being extremely important to TSMC, but there’s also important companies to ASML, like Carl Zeiss, Cymer, Trumpf, if I’ve got all those names right.

[00:14:41] But um, yeah, who are the important suppliers to ASML and why? And do you wanna talk about the supplier aspect? ,

[00:14:46] Jon (Asianometry): I think Carl’s Ice is probably the most well known one. I think the interesting thing is Carl’s Ice actually has a joint venture with ASML. So it kind of emphasize when I was working on that video, I was thinking a lot about how much that ASML really focuses on owning the certain parts of the technology that are critical to them.

[00:15:02] Right. When Cymer laser providers kind of, reach certain requirements. They, they acquired the whole company. but at the same time, the company is like Boeing in that they want to sit at the very top, they want to own all the value.

[00:15:15] Right. And when they don’t really let and get themselves in a situation, in my opinion, that they, they, they, they want to where they’re gonna allow themselves to be leveraged by, by a supplier, otherwise they’ll acquire that company. Really, if you think about what’s kind of the most important parts of, if you think about what makes the EUV bring its value, right?

[00:15:36] You think about the different parts of it. You know, a lot of that is already owned or partially owned by ASML, If you think about there’s, you have to break it down. You have the mechanics, the machines, the mechanics moving, the wafers parts. You have the light source, you have the optics, you have the photoresist, which I think, uh, actually it’s not provided by ASML.

[00:15:59] and I think that’s it. But like, so the, so I think all of those are very, very closely controlled by ASML. So in general, what I’m telling you is that, you know, they have a lot of suppliers and the ones that are ever important, you’ve tended to have already called out.

[00:16:13] Kalani Scarrott: Ok yeah fair enough. And with the power, given that ASML are the only company that makes EUV machines and they’re used by all major global semiconductor chip manufacturers, like the layman might ask the layman being me, why does ASML not seek vertical integrations?

[00:16:29] So in the sense of competing against TSMC and the like. So I think you said, I think some people may wonder if ASML has a monopoly on EUV machines, what stops ’em from competing in the fabrication space.

[00:16:39] Jon (Asianometry): I think the big thing to point out is that TSMC has been doing fabrication for 30 plus years.

[00:16:46] Samsung is backed by immense Chaebol and I would say that just because lithography is the most charismatic, it’s the most popular part, uh, it’s the one everyone thinks about semiconductor manufacturing. It’s not the only one. There’s other things like etching, deposition, packaging, testing, what not. all those parts have to be integrated into the clean room when TSMC makes those chips.

[00:17:10] So the expertise, TSMC brings the tables not to how to build like a complicated Lithography machine. And ASML wouldn’t be good at that either, I would say, uh, wouldn’t be good at kind of putting all that part just the same way as, TSMC doesn’t know how to build a machine. ASML doesn’t know how to use that machine along with all the other machines that need to be used.

[00:17:29] to make a full chip. And I also think, you know, it’s, it’s unlikely that ASML will make their money back if they’re not selling to other clients, right. If they’re just, if they decide to go and compete with their own customers, they’re not gonna make their money back.

[00:17:44] They need to sell to like a Samsung, they need to sell us to an Intel. They need to sell tech to TSMC. And that was one of the geopolitical risk for ASML. Like they needed to pay this incredible investment back. And they might have made a lot of that back if they had were able to sell to SMIC, to Hua Hong and all those other companies.

[00:18:02] so that was something that wasn’t allowed to them by American laws.

[00:18:06] Kalani Scarrott: Perfect tie in for the next question. So with the trend of de-globalization and supply chain security, are they a threat to ASML’s asset light model, which uses a tonne of suppliers?

[00:18:15] Jon (Asianometry): You know, I actually looked into this and I, I see, and I think, I believe like over nearly 50% of ASML suppliers are within the EU.

[00:18:23] So a large portion of ASML’s, uh, supply chain is pretty localized. de-globalization is something that I think every company in the semiconductor industry is trying to practice. They’re trying to bring more of that in-house. I think they’re go, I think they’re going about it the way that they’re, they’re, they’re best going about it. I think it works.

[00:18:42] I think it works.

[00:18:43] Kalani Scarrott: No, fair enough. And sorry, I’m jumping around questions here cause my mind jumps around as well. But, um, I picked up in one of your videos, could you just explain why zero deffectivity is one of EUV lithography key challenges to overcome?

[00:18:54] Jon (Asianometry): It was one of the one when people were kind of going through the zero deffectivity or the various problems, the deal breakers to what would make EUV lithography a real thing.

[00:19:05] Zero deffectivity was kind of the biggest ones, right? The problem was. defects on the mask are very significant. They have a huge impact. So if you have one problem, so if you think about back to the stencil, right, that photocopier where you’re trying to make bunch of wafers. If you have a problem with your stencil, with your design on your mask, and you print wafers like tens of thousands of wafers, it could be actually a long time before you discover that there was a problem on the chip.

[00:19:33] Could be when the chip test when you run the test on the chip, the chip doesn’t perform well and you don’t have, you have no idea why that came out, like why it came out that way. and it’s a huge problem because then suddenly you’ve wasted tens of thousands of dollars or tens of thousands of wafers, which means millions of dollars, and now you’re in a huge problem.

[00:19:50] so one of the biggest problems with when they were trying to build what EUV was, was how to prevent those defects from ever happening. And also making sure, and it’s even more challenging because with EUV, that mask, that photo mask, the radical. is not transmissive, meaning that light is not going through it.

[00:20:09] Light reflects off of it. And if you know kind of how mirrors work, that means every line, every, every part of that mask design on that has to be perfect. so that’s just one part of it, right? So producing the mass, making sure there’s no bumps, there’s no. Defects on the, on the blank itself.

[00:20:30] That’s number one. And then number two, you have a situation where you have to prevent particles from landing on the mask and interfering with the, with the light on the exposure process, which is doubly difficult because you don’t have any, early on, you didn’t have any protections from keeping particles getting into that EUV machine..

[00:20:50] So you had to kind of zero out the whole thing, go into total into as good of a vacuum as you possibly can and that has a substance, significant amount of cost. And so eventually they got to create what they call the pellicle, I think they use carbon nanotubes as far as I know, which is crazy. And it’s crazy that they found a material that actually allows EUV light through.

[00:21:14] And does not only have to let EUV light through once, but twice without absorbing too much of that light. So as a go through one time as it hits before it hits the mirror, and then after when it, after it hits the mirror. So that was one of the biggest significant issues with creating those blanks, and it was a process that couldn’t start that first, could not start until they had a tool to actually test it.

[00:21:40] And then from then it took, I would say, multiple years for them to finally reach acceptable levels.

[00:21:46] Kalani Scarrott: Yeah, just, it’s just crazy cause I was reading as well. The flatness in EUV machine mirrors are just insane. So the mirrors are polished to a smoothness of less than one atoms thick. So to put into perspective, if the mirrors were the size of Germany, the tallest mountain would be a millimeter high.

[00:21:59] Is that true? Like, what is it, explain this to me. Explain the magic.

[00:22:02] Jon (Asianometry): It’s, it’s, it is, it’s, it’s crazy. These mirrors are insane. And the reason was because virtually every material that could have been used does not let 13.5 nanometer wavelength light through. So, like I said, there’s no transmissive materials in an EUV machine.

[00:22:21] It’s all reflective. So when they moved to a reflective optics, there was a totally different paradigm and each mirror has, it’s kind of crazy how these mirrors are made. Like they’re, they have 50 pairs of aluminum and silicon, and each one of those, each layer pair by itself is seven nanometers thick. They’re grow.

[00:22:42] Actually, I would say what the way they’re growing is actually not that actually surprising or not that surprising. They use deposition and so they basically grow these things.It kind of reminded me how they use similar vapor deposition procedures to make synthetic diamonds. hmm.

[00:22:59] Which, So basically the whole point is that they wanna make sure that you preserve as much of the light as possible when you bounce off the mirror. And even so, even if the mirror is made perfectly, you only reflect 70% of the light at its maximum.

[00:23:13] Kalani Scarrott: Wow. God. cause Yeah. Even the same thing I saw in your video, even the size of a virus can cause problems down the line, like something so miniscule

[00:23:20] Just ruins the whole batch. Unreal. And on the economic side of it, are we even able to build a simpler, cheaper EUV machine?

[00:23:27] Jon (Asianometry): I think it’s a good question. I think it’s, I think we can build like a tiny fund science project pretty easily. I think the question is whether you can use that project to create tens of thousands of N3 or N5 wafers in an industrial setting, right?

[00:23:43] One of the reasons why EUV took so long was because the power source, like I mentioned, so I think like you could have inserted it into the 90 nanometer process note like it was originally asked for, but at that time, I would doubt such a device would be economically viable against like a $5 million DEUV 193 machine.

[00:24:07] So I think that was one of the big problems was that EUV, when you run it through a process node, the process node is nothing more than a manufacturing line, right? So when you run it through that process node, you’re not only using EUV machines, you’re EUV exposures or EUV layers. So there’s a lot of DEUV 193 immersion systems still in there.

[00:24:29] And they’re, they’re used because they’re work horses, they’re very reliable and I don’t see EUV ever getting to a point where they replace DEUV machines where they would rather use an EUV machine if they didn’t have to. Does that make sense?

[00:24:45] Kalani Scarrott: Yeah. And if I’m right, as you go to newer nodes, so DEUV obviously can produce a lot quicker and more than an EUV machine, is that right as well?

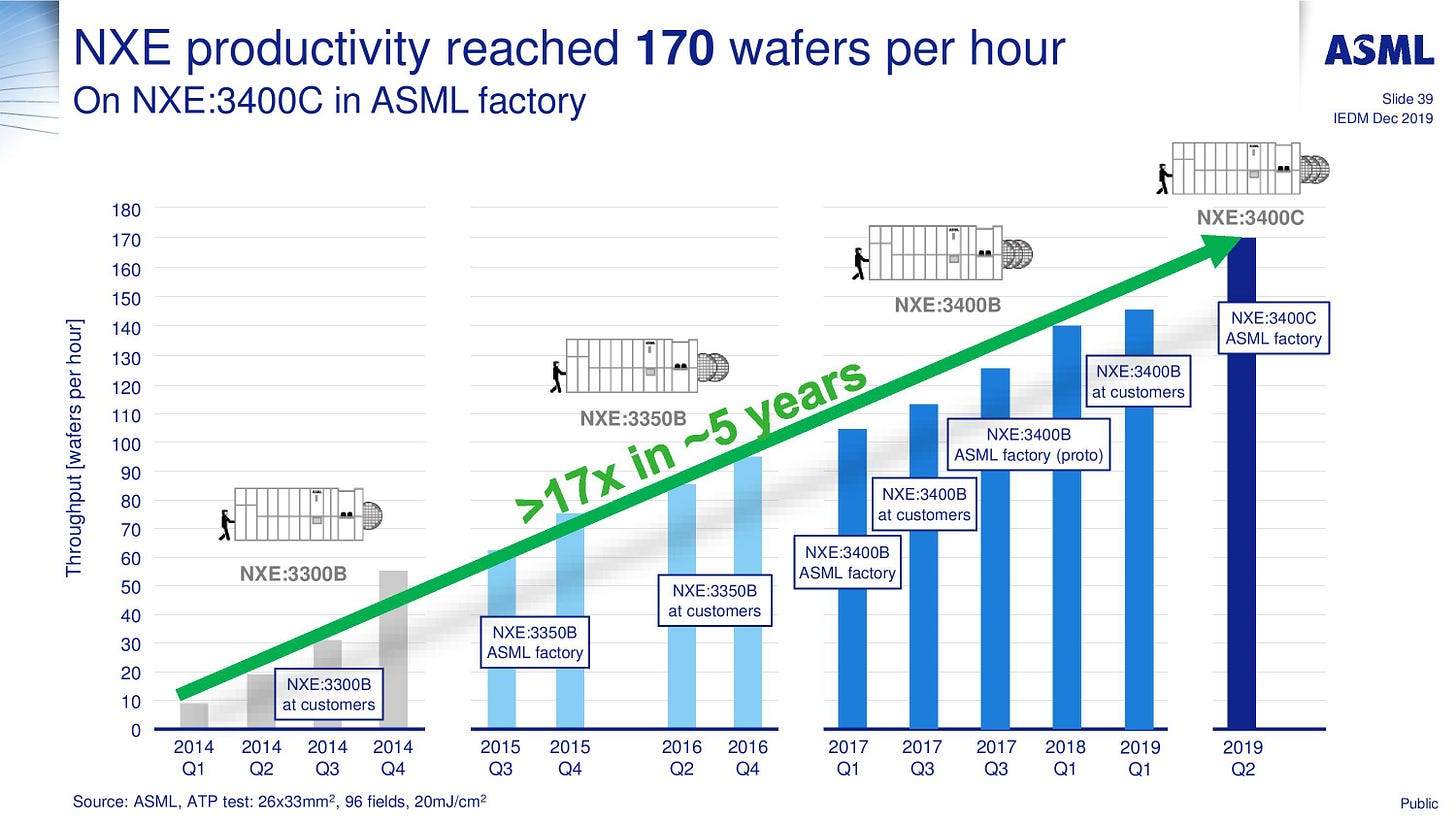

[00:24:53] Jon (Asianometry): Yep. The throughputs higher.

[00:24:56] Kalani Scarrott: Yep. If it gets harder and harder how do you even combat that?

[00:24:56] Jon (Asianometry): And you don’t have to have all these restrictive maintenance, right? Like EVU is a very delicate, the whole thing barely works. I would say. Uh, it works pretty well, but it barely works. so a DEUV machine, I think is far more, far more effective.

[00:25:14] Kalani Scarrott: And EUV it was such a joint collaboration. It was such a mammoth feat to get there in the first place. What the hell’s next? How do we go to take that next step?

[00:25:23] Jon (Asianometry): You know, I was reading an article with like the as ASML CEO, or maybe it was the CTO or something, but they were saying, they were talking about what they were trying to deliver.

[00:25:30] They’re trying to deliver high NAEUV, right? Which is where you raise the numerical aperture of the EUV machine so that it collects more light and you can get a smaller, uh, critical dimension. But what is after that? Right? And there’s something called, there’s a something called Hyper NA. So hyper NA is kind of like how, uh, immersion lithography raised the NA of the 193 nanometer light.

[00:25:56] Right. To, to make it, to, to improve the critical dimension even more. Right. so that is the next, that would be the theoretical next step of EUV, right? because they don’t, I don’t think they’re gonna move away from that wavelength light anytime soon. The only problem was that the high NAEUV machines are already incredibly expensive.

[00:26:15] They, they’re $300 million, right? Or something like that. And that’s like, what, how many co, how many companies are gonna buy a high NAEUV machine, like $300 million in their pocket? What’s next? I don’t think they have, I don’t think that’s how the semiconductor industry works. They know what we’ll do in the next five years, but anything after that, like, they don’t, they have no clue.

[00:26:40] They, they, they’re, they have to look into it and they’re kind of, they’re kind of, you know, feeling their way through the river. They’re, they’re making their way across the river by feeling the stones on the bottom. So I think they are very poor at making predictions after five years. We don’t know. We don’t know what would be next.

[00:26:57] There could be other things like what are they using to etch the masks themselves. They’re there, there’s a very, you can basically use electron beams to write, uh, even at even small, at feature sizes, even smaller what EUV can do. But the difference that makes EUV more effective than other, Then other things then, then tech, then Techn Technology is that, that is that you can still use EUV to get the scale right?

[00:27:22] You can flash entire, you can still step and scan across the whole wafer to do many designs exposures at the same time. It’s kind of like, you know, you’re still printing as opposed to handwriting a signature, right? If you’re handwriting every signature, every time, that’s gonna get tiring. Where if you just stamp the signature over and over.

[00:27:43] And defects too, I’d assume would be better. Defects are always a problem. Uh, defects are always a problem.

[00:27:48] Kalani Scarrott: So this was a question submitted. I have to give credit in the show notes cause I don’t have it written down who it’s from. But what kind of threat is the emergence of 3D DRAM that places more emphasis on etching and other processes rather than lithography?

[00:27:58] Jon (Asianometry):I need to talk about this DRAM thing for a second. Cause like everyone keeps complaining to me. “Jon, you don’t know how to speak dram. It’s D-ram”. and the only thing I have to say is that first my father said DRAM, so I grew up thinking it was DRAM. I did my first videos about it, and then people started yelling at me like really angry.

[00:28:21] I kept emails just saying, I like your videos, but I cannot accept the way you DRAM, you don’t know how it’s pronounced. I know how it’s pronounced, but I can’t lose face and change it. I have a face. It’s, it’s a, it’s Asian culture. Y’all guys, y’all gotta understand you gotta save face. Anyways, so 3D memory has been around for a while, right?

[00:28:44] Actually, so the technology has been around. So we’ve, we’ve had 3D dram, we’ve had 3D image sensor. That’s been around only recently we have been able to achieve like true 3D integration on Logic chips using what are called through Silicon Bios tsb’s is this a threat to lithography in a way?

[00:29:04] Yes. I do agree that that has a risk of kind of taking away some of the supremacy that lithography has within the manufacturing chain, because lithography has sort of, kind of petered out after 50, 60 years, you’re gonna see a possible de-emphasis on lithography and more emphasis on other parts of the manufacturing process like etching, like deposition, but also packaging as well.

[00:29:30] I think that’s, you know, it’s a challenge for ASML because they’ve staked a whole lot on lithography, right. And You know, they’ve sucked out a lot of the investment of that industry, and if they cannot continue to bring down more economic, viable lithography machines down the line, that money, that investment still needs to go somewhere.

[00:29:49] And so you’re starting to see, you know, you have, you have situation when you see something like TSMC and they’re doing a lot of their advanced packaging in the house. Right. that’s interesting, you look at that and that’s kind of a situation where, it’s kind of like when you start seeing your best customers kind of buying other, other products.

[00:30:10] So, you know, but at the same time, I, like I said before, it’s hard to see what’s coming down the line like five years from now. So there is a future where, You see a lot of investment in all these other parts of technology where lithography, basically stagnates, where we usually see incremental improvement on certain, certain aspects.

[00:30:32] And that’s hard because you’re not gonna have those replacement cycles going through.

[00:30:36] Kalani Scarrott: on the topic of emails, people complaining about your pronunciation, but also in our last deep dive, you mentioned as ASML employees often email you. So I’m just curious, what’s the common reason for why they email you?

[00:30:47] Jon (Asianometry): They’re very nice people. they’re, they’re very nice people. I think. I think TSMC is just more closed as ASML is a lot more open culture I think they’re more open to it. And, tsmc, they’re very closed. And they also speak Chinese too. So, I mean, most of ’em don’t watch the videos anyways. they’re very nice people. I, I really enjoy ’em. And I think they have, they have a lot.

[00:31:05] They’re really not only really passionate about what they do, they have incredible pride because they’re working what is now one of Europe’s most prestigious manufacturing companies. It’s basically the only manufacturing company other than perhaps Airbus in the top 100. So I mean, they’re very, people have a lot of pride over it.

[00:31:23] Kalani Scarrott: Yeah even just reading through a lot of your YouTube comments for research for this video, it is so helpful and people are so keen to share their thoughts and their experiences. Um, yeah. You’ve got a good group of fans sometimes.

[00:31:33] Jon (Asianometry): Yeah, they’re nice. A lot of them are nice. The mean ones. The mean ones are quite mean, but yeah.

[00:31:40] Kalani Scarrott: So obviously with all your notes, anything else we haven’t covered that’s consequential about the future of ASML and EUV in your opinion?

[00:31:46] Jon (Asianometry): No, I think, I think we’ve covered, we’ve covered a lot in very short amount of time. I think it’s very interesting to see, I wanna learn more about hyper and NA EUV down the line.

[00:31:57] And I also really would be curious to know about, in the future what can they do to fix this power consumption problem? Cause this power consumption of these EUV machines basically makes EUV unacceptable for vast number of companies, right? 6% of Taiwan’s entire energy consumption is basically to TSMC, a single company.

[00:32:23] and that goes up higher every time they buy a new EUV machine. Right. I’m very curious and I think a lot about what ASML can do to reduce the power consumption on these machines. Especially when you get to even more advanced products And what consequences will that have for the chips themselves too. That’s more of a TSMC thing, but it is very curious to me.

[00:32:46] I see that as one of the big problems with semiconductor manufacturing and its environmental impact.

[00:32:52] Kalani Scarrott: I still remember you talking about water consumption at TSMC, and I thought that was so interesting and the problem there and how they solve it, and yeah, just the science behind it.

[00:32:59] Jon (Asianometry): You know, actually I was at, when I was during my visit, I noticed that, uh, in southern Taiwan, uh, I noticed that they have built, they’re carving out a canal.

[00:33:10] A canal that would bring water from the ocean or from a reclamation plant near the ocean. And they’re bringing that to a massive reservoir. There’s not just one massive reservoir there’s like multiple around these fabs. It’s literally sitting next to the fab. It’s kinda like some nature area, but it’s a huge lake and

[00:33:31] They, yeah, they’re, they’re doing some incredible water projects down there, and I think that’s something to, uh, the water consumption. Of course, everyone talks about that. It’s a big problem, especially in Arizona. it’s curious to see how they’re tackling it in Tainan, because, yeah, it’s just, it’s just amazing.

[00:33:50] Like, just visiting these plants is amazing.

[00:33:55] Kalani Scarrott: Because it’s like a whole little compound complex, kind of hard to even imagine. Mini city, isn’t it?

[00:33:59] Jon (Asianometry): It’s a, it’s a city. It’s basically a small city. Cause uh, like that fab, so there’s Fab 14, fab 18, those are the two big ones. And Fab 18, which I visited and you can, it will take, a good maybe two to three minutes to scooter around that.

[00:34:15] And it takes 30 to 40 minutes to walk. and they’re building phase seven, and when I was there, they, they have like four projects going on, like multiples. It’s crazy. And like they’re bringing in, they’re, they’re probably gonna fill these things with some of these crazy EUV machines too. Like, it’s it boggles to mind just the infrastructure, not just on the water side, but the electricity side that is necessary to make the single fab.

[00:34:42] Kalani Scarrott: Bloody smart humans behind all this. I love hearing about stuff like this, but, yeah. I’m curious about your take on this, given your knowledge, insight, but does it worry you, or how do you think about how much of the world economy is dependent on so few companies?

[00:34:55] Jon (Asianometry): I’ve heard a lot about this, so this is the first time, I’m probably gonna say this on anywhere, but like, uh, I think, I don’t think the world economy is that as a world economy right now is dependent on, on advanced semiconductors. Right?

[00:35:13] Advanced semiconductors are sort of to the techno, to the rest of the economy and to, to policy makers. They’re seen as like, they’re almost like a, like a pathway to a better future in some way. It’s like your option for a better future. In reality, what I’ve noticed is that the majority of semiconductors that actually run your life are very small, are very old, very small, and very, very just normal.

[00:35:36] there are 200 fabs around this world, and many of them I think are, are of those types. They’re, you don’t really notice them. They’re quite small and like, uh, they, they just, they just turn out and they, they make money. They make, they probably make good money and they, they, they just run until someone tells ’em.

[00:35:52] No one buys their output anymore. I think most people will never use an N2 or I guess most, a lot of people will actually, a lot of people will use these chips cause they’re going in smartphones. But, but other than that, like a lot of people are not gonna really see their lives change because of the N5 or N3 chip as compared to some of these dollar chips.

[00:36:15] I like to think that these chips are like, like, like bodybuilders. They’re optimized for one thing and they’re not really survivable in the real world. I kind of, so I hesitate when people say like, the world economy is dependent on so few companies. there are a lot of other companies that are much more. They’re much more important to the world economy, I would say.

[00:36:34] You know, like your energy companies or your. food companies or logistics companies or something like that. So I think it’s, it’s, it’s just, you know, it’s still kind of, still kind of weird for me to think about it. Maybe I’m wrong. I think there’ll be plenty of people emailing me saying like, you know, Jon, advanced Semiconductors don’t, the only way we can tap, you know, we can enter the go to Mars or something, or like find the future.

[00:36:58] But I generally don’t agree with that.

[00:37:02] Kalani Scarrott: That’s fair enough cause I’m a noob talking about this, but reading chip war, hearing you, it does seem like we’ve reached a luxury point whereas before it was better chips for a better military. You know what I mean? There’s a bit more on the line. It felt, I don’t know, that’s just my takeaway so far.

[00:37:14] Jon (Asianometry): It’s kind of curious cause I was like, you know, I’m doing, right now, I’m doing a video about kind of what Europe lost in the semiconductor industry, why they fell behind in the semiconductor industry. And one of the big reasons, or one right, early, very early on, one of the things happened is that, you know, they decided to de-emphasize work on semiconductors to build, nuclear, nuclear, nuclear, nuclear to build weapons, essentially to build the biggest weapons.

[00:37:42] And I think it’s kind of interesting to see that certain policy choices made by countries at certain times had kind of big reverberations down the future.

[00:37:53] Kalani Scarrott: Just like chip manufacturing, I guess one small little defect amplifies out. So honestly choose a million for coming on today. Like at the start there I was almost in tears.

[00:38:02] I was like, this is the greatest day of my life. It’s like watching a genius at work. I genuinely mean it. It was freaking insane. So, um, yeah. Thank you so much. Anything you wanna plug, I’ll link all your videos to your playlist. ASML playlist.

[00:38:13] Jon (Asianometry): Oh my gosh, uh, no, everything’s good. I’m, I’m, thanks for taking the time, uh, on short notice, by the way.

[00:38:22] It’s. We’re trying to make this recording before I come down with covid. So I really appreciate it. And, um, and, you know, watch Asianometry Channel everyone, and, and feel free to email me if you, uh, wanna say hi.

[00:38:37] Kalani Scarrott: Perfect. Always more than welcome.

Subscribe to Compounding Curiosity

Interviewing interesting people across Asia-Pacific.